Hello guys,

lately, I've been struggling with some of control loops in my plant. I've tuned loops as many of us would do, by trial and error. I couldn't get meaningful information by bumping process with step CO change (as suggested in the article on controlguru.com). I was able to find satisfactory response and I'm fine with that. While trying to improve control performance I 've read some of the articles posted on controlguru.com again. Most interesting I find is the part about anti windup integral logic that was described in the article(http://www.controlguru.com/2008/021008.html).

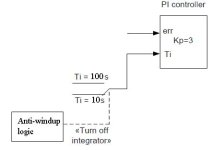

Now, I saw how some people implements this windup protection, but I have a hard time to understand what is described in "solution 1":

"With our controller properly initialized, the approach is to flip the algorithm around and back-calculate a value for the integral sum of error that will provide a desired controller output value (COdesired)"

inegral(error) = (COdesired-CObias-Kc*error)/Ki

What does this really means? Is it like sign of integral action is reversed?

Also one more thing. In the second article about concrete implementations of PI controllers that uses multiplicative form (position PI form used in controlguru), I read something like this: "Integrator is provided with corrective element which reduces integral reset time in case of large control deviation (error value = SP-PV)". In this position PI form it means that overall integral component of PI controller will be increased since reset time is reduced. So this doesn't fit the story about windup prevention.

I'm a little bit confused about this and like to make this clear with your help.

Thanks

lately, I've been struggling with some of control loops in my plant. I've tuned loops as many of us would do, by trial and error. I couldn't get meaningful information by bumping process with step CO change (as suggested in the article on controlguru.com). I was able to find satisfactory response and I'm fine with that. While trying to improve control performance I 've read some of the articles posted on controlguru.com again. Most interesting I find is the part about anti windup integral logic that was described in the article(http://www.controlguru.com/2008/021008.html).

Now, I saw how some people implements this windup protection, but I have a hard time to understand what is described in "solution 1":

"With our controller properly initialized, the approach is to flip the algorithm around and back-calculate a value for the integral sum of error that will provide a desired controller output value (COdesired)"

inegral(error) = (COdesired-CObias-Kc*error)/Ki

What does this really means? Is it like sign of integral action is reversed?

Also one more thing. In the second article about concrete implementations of PI controllers that uses multiplicative form (position PI form used in controlguru), I read something like this: "Integrator is provided with corrective element which reduces integral reset time in case of large control deviation (error value = SP-PV)". In this position PI form it means that overall integral component of PI controller will be increased since reset time is reduced. So this doesn't fit the story about windup prevention.

I'm a little bit confused about this and like to make this clear with your help.

Thanks

Last edited: